It’s the end of a long day touring a commercial greenhouse growing operation in Colorado. We’ve covered so many topics, from nutrients, water quality, guttering, and drainage systems to fuel bills, growing media, strains, and lighting. Darryl, the head of cultivation, reaches into his pocket for some rolling papers. I ask him which of the facility’s forty-five cannabis strains he’s smoking today.

“Oh—none of them. I get my head stash from a hippie girl down the way for 200 bucks an ounce.”

My surprise is greeted with collective laughter; evidently his co-workers all agree.

“None of us smoke the stuff we grow here.”

What? Not even with a generous employee discount? Seriously, these guys—seasoned commercial cannabis cultivators and consumers—were the last people I expected to be paying a premium for their smokes—and yet this scenario is far from uncommon.

Mass-produced, large scale commercial cannabis is invariably regarded with disdain and contempt by cannabis aficionados as bland and generic. It piques their interest as much as a multipack can of Bud Light excites beer geeks.

This raises the question, what are some cannabis growers—or cannabis growing operations—doing differently that commercial cannabis producers aren’t—or can’t?

This conundrum lies at the center of a longstanding debate in the cannabis world between traditional, smaller ‘craft’ cannabis cultivation versus large-scale commercial cannabis. It doesn’t help that definitions of ‘craft cannabis’ and ‘commercial cannabis’ vary widely in their scope depending on who you talk to. While most growers agree that the term ‘craft cannabis’ originated in the Northern Californian outdoor growing scene, the line where craft cannabis ends and commercial cannabis begins remains appositely fuzzy. When I discuss this with my hosts in Colorado, it’s clear that the distinction is more nuanced than growing operation size alone; there are many other factors at play.

“Hippie girl cries on harvest day and says a little prayer of thanks for each plant.”

Apparently, this particular ‘craft grower’ becomes very attached to her plants during their life-cycle. They refer to her as an ‘EQ grower’ rather than ‘IQ’—it’s all about emotions, energy, and feeling. She cultivates her plants in large wooden beds filled with rich, organic living soil potting mix. Each plant receives a far greater number of ‘touches’ (aka human attention) than would be economically feasible in a large-scale commercial growing operation. Careful pruning, bending, shaping, top dressing, hand-watering, foliar feeding, whole plant drying, hand-trimming—you name it. These plants sound like the botanical equivalent of Wagyu cows!

‘IQ growers,’ on the other hand, are far more data-driven; they check their smartphone for what their plants need. Sap tests, lab reports, mineral nutrient auto-dosing, drip irrigation, stone wool grow blocks, machine trimmers—the IQ grower in a commercial cannabis growing facility inhabits a very different world.

Is there a middle ground? Rest assured, this isn’t a reference to mid-grade produce or ‘mids’—it’s an inquiry into whether there is a way to efficiently and economically produce ‘craft quality cannabis’ at a larger, more commercial scale—and hopefully without any tears.

Labor costs will always be a key concern for commercial licensed cannabis producers, so adopting SOPs that don’t necessitate extraneous transplant stages, for example, or complex defoliation strategies, or any other labor-intensive activities is a given.

Are there any tactics available to all growers, wherever they reside on the cannabis cultivation continuum, that can help to boost both quality and productivity?

Arguably the most effective place to start is ‘one-off actions’—those ‘extra miles’ that are relatively quick and painless to implement but deliver benefits across the entire life-cycle. The obvious example here is the choice of growing medium. Investing in a superior coco mix or soil-based potting mix requires some knowledge of the market and, perhaps, a few extra dollars. Whether a cheap, entry-level substrate is used or a premium mix that meets high standards for cleanliness, consistency, air and water ratio, as well as overall performance, the pots still take the same time to be filled! Practical training of cultivation staff is also essential (i.e. tapping the container on a hard surface when half-full to get rid of any large air pockets) in order to make the most of any upgrade in media choice.

Craft growers enjoy a lot more agility in terms of adapting their grows to the needs of specific strains. Enlarging the final pot size from, say, five gallons to seven-and-a-half gallons can be very beneficial for some more vigorous cultivars as root zones have the opportunity to increase significantly in mass while the risk of salt build-up or drought is mitigated by larger containers. Commercial growers, on the other hand, need to weigh very carefully whether a fifty percent increase in the volume of growing media required for each run will deliver the extra yield they need.

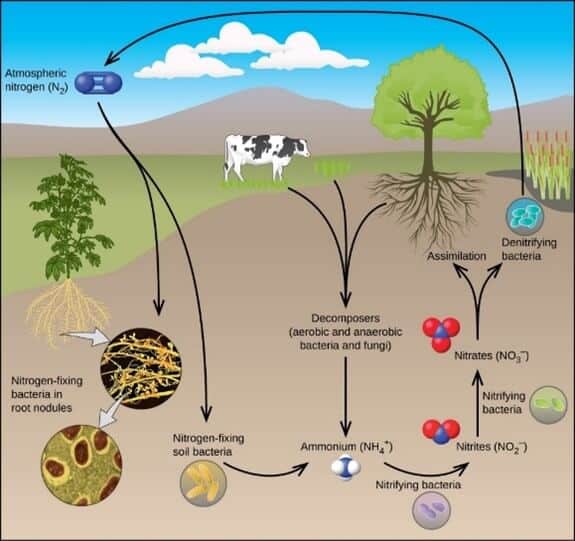

What about feeding strategies? Some craft growers try to pack as much nutrition into their living soil mixes as possible up-front in the form of powdered and micronized organic inputs, whereas other craft growers prefer to start with a lighter mix, opting to supplement nutrition when needed through periodic top-dressing and organic liquid feeds.

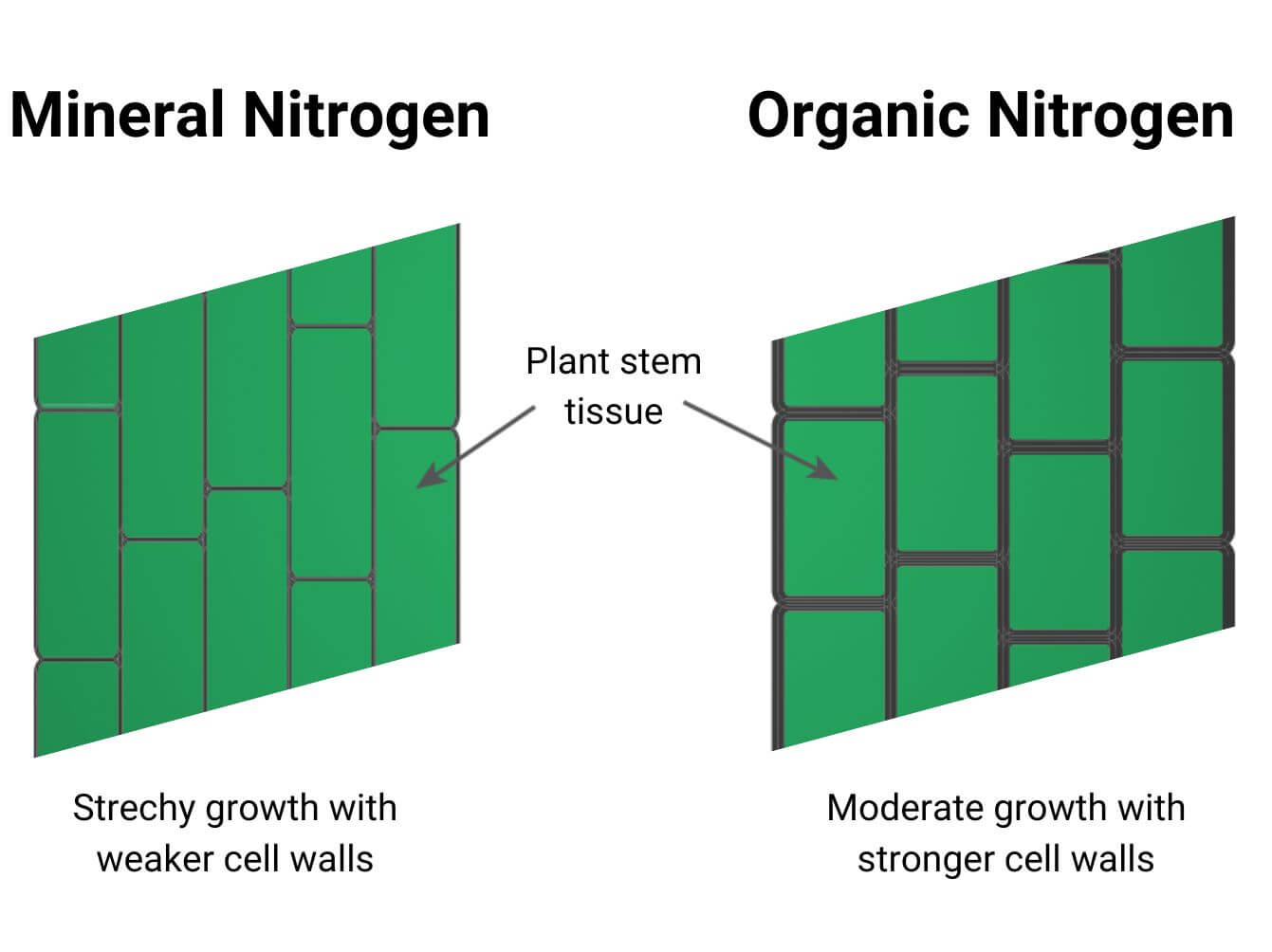

Commercial growers tend to gravitate towards soilless substrates to minimize the risk of pests; mineral base nutrients are dosed, often inline, and run to waste. It’s essential that all nutrients and additives used are dripper safe (won’t clog drippers and drip lines.) If reservoir tanks are used for nutrient solution batches or recirculation, any additives need to be reservoir stable. This requirement effectively prohibits the use of many amino-acid based additives that can stimulate terpene production in cannabis.

Strain selection is an interesting area for comparison. Commercial growers have more space to grow out seedlings and hunt for potential mother plants. While some operations rely on specialized clone producers, most take care of propagation and genetics preservation in-house. Craft growers can leverage significant advantage through long standing cannabis cultivation networks where cuttings are traded and shared. Plants are selected, not just for productivity, but for distinctive terpene profiles, shelf-life, bag appeal and potency. The scale of craft operations tends to favor more agility in the marketplace, so new strains can be introduced, tested and brought to market quicker.

Do expensive additives really make a difference in cannabis yield and quality?

The cost of additives sure adds up! Whether it’s mineral enhancements like PK boosters, enzymes, natural growth regulators or microbial products, all cannabis cultivators must do their utmost to avoid overlapping or extraneous products lingering in their feeding regimes and instead single out the best value boosters that truly deliver on multiple fronts. Look for the maximum ‘bang-for-buck’ in your boosters, ideally multi-action additives that not only enhance the production of secondary metabolites but also increase yields, improve resistance and optimize beneficial biology. Remember to calculate not only the cost per application gallon but also to take into account whether the additives are designed for use throughout the lifecycle or if they are optimized for targeted deployment, typically from the middle of the generative stage. Experienced growers know that it can become increasingly difficult for plants to access all the nutrition they need throughout the flowering phase, especially as roots fill containers and the water holding capacity of the media is reduced.

Craft Cannabis versus Commercial Cannabis is a False Dichotomy

While craft growers highlight the care and attention they give their crops, commercial growers tend to favor the talking points of precision, consistency, and control. In reality, the essence of quality cannabis transcends these boundaries. The most successful cultivators, craft or commercial, embrace the best practices across the spectrum, from the emotional intelligence of craft growers to the technological prowess of commercial producers. In this light, the narrative of craft versus commercial cultivation evolves from a polemic into a dialogue, one that celebrates the collective achievements and continuous learning that propel the industry forward.